Rotary Tables 101: Functions, Categories, and Applications

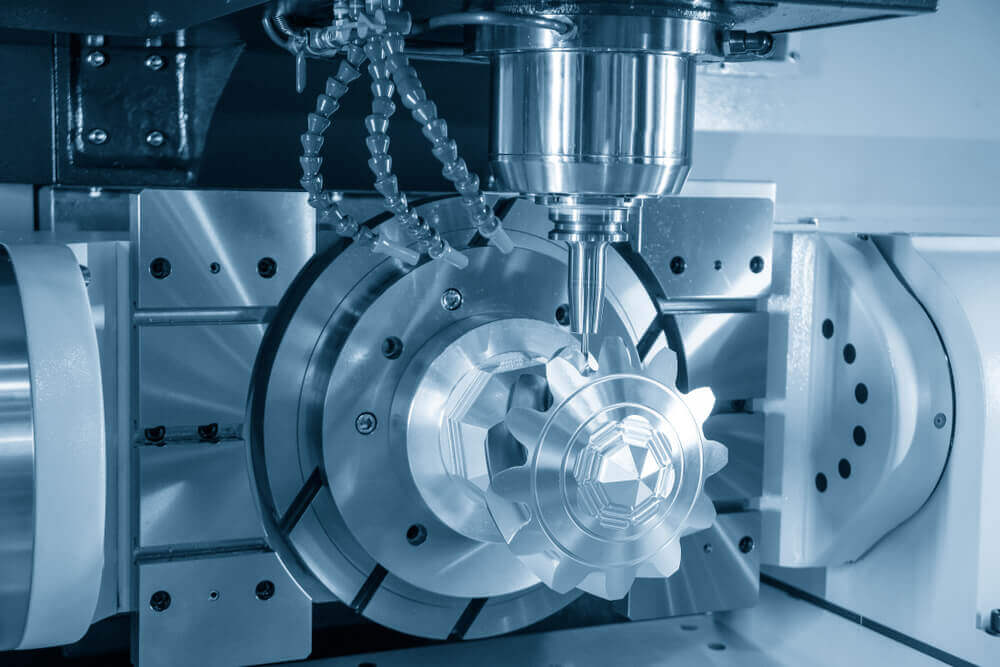

Rotary tables are the unsung heroes of precision machining, quietly playing a crucial role in achieving the accuracy required in various industries. These mechanical devices, either manual or automated systems, facilitate controlled rotation of workpieces, allowing for precise angular positioning and enabling tasks like indexing, drilling, milling, and more. In this article, we'll delve deeper into the world of rotary tables, exploring their functions, categories, and versatile applications.

Functions and Categories of Rotary Tables

Rotary Tables’ Major Functions Include Indexing, Multi-Sided Machining, and Helical Milling

Rotary tables are indispensable in enhancing the efficiency and precision of machining processes. The major functions of rotary tables include indexing, multi-sided machining, and helical milling.

Various functions that rotary tables offer:

- Indexing: Rotating the workpiece of the cutting tool to a specific angle or division allows for precise machining operations at regular intervals.

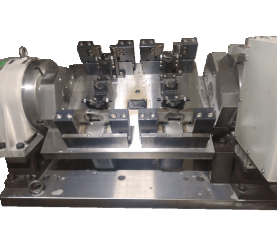

- Multi-Sided Machining: The rotation of the rotary table also takes away the need to reposition the workpiece, saving time and ensuring precision.

- Contouring and 3D Machining: The rotary table allowed for the creation of complex 3D contours and shapes.

- Undercut Machining: The ability of the rotary table to tilt and rotate allowed for undercut machining, where the cutting tool can access areas that would otherwise be unreachable with standard machining setups.

- Helical Milling: Rotary tables allow the cutting tools to follow a helix path to create threads or helical grooves in a workpiece.

- Dividing and Spiraling: Rotary tables can be used for dividing a circle into precise divisions or spiraling patterns for artistic or functional milling application.

- Angular Drilling and Boring: The ability to tilt a rotary table allows the drilling or boring of holes at angles other than the vertical or horizontal orientations.

- Gear Cutting: Rotary tables are used in gear manufacturing to perform gear cutting operations.

- Engraving and Marking: Rotary tables enable precise engraving or marking on a curved or contoured surface.

Different Categories of Rotary Tables That Suit Various Manufacturing Environments

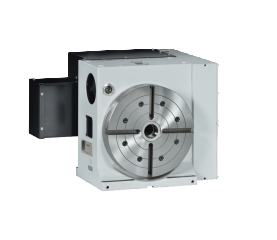

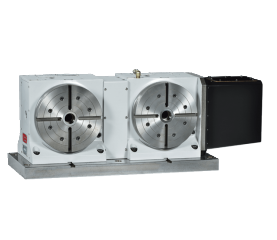

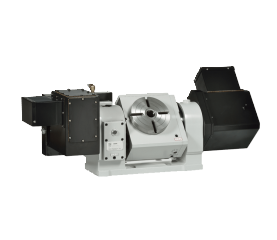

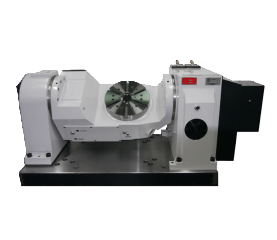

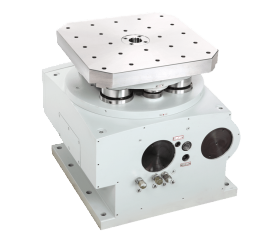

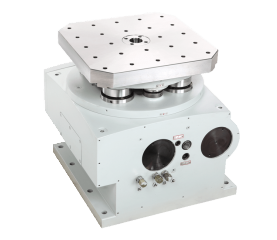

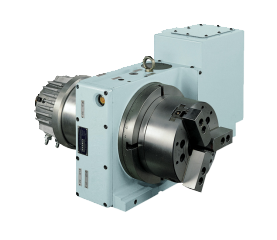

- 4-axis: Enables the rotation of a workpiece or a cutting tool around four different axes, providing greater flexibility and capabilities for machining complex geometries and performing multi-sided operations. The 4-axis rotary table extends the capabilities of CNC machining, allowing manufacturers to produce more sophisticated and precise parts more efficiently.

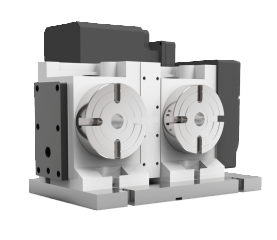

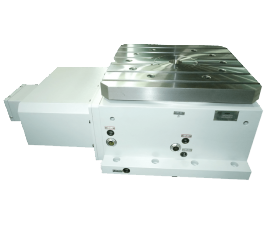

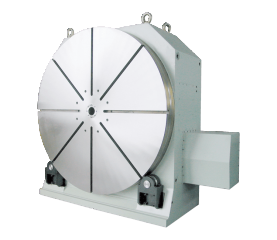

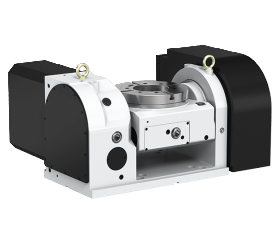

- 5-axis: Compared to a traditional 3-axis machine, a 5-axis rotary table introduces an additional tilting axis and a rotational axis. This enhanced capability allows for even greater flexibility and precision in machining complex geometries and performing intricate operations. The 5-axis rotary table is a high-performance tool used in advanced manufacturing environments, where complex geometries, tight tolerances, and sophisticated machining operations are required.

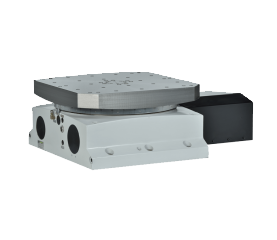

- Pneumatic: Uses pneumatic power, usually supplied by compressed air, to drive its rotation. It is designed to provide controlled and precise angular positioning of a workpiece or a cutting tool. Pneumatic rotary tables are valued for their compact design, relatively simple operation, and cost effectiveness in automation processes.

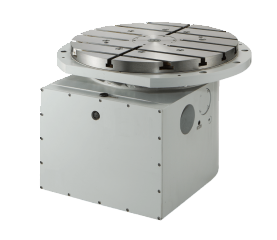

- Hydraulic: Utilizes hydraulic power to drive its rotation. It is commonly used in various industrial applications where precise and heavy-duty indexing or rotation is required. Hydraulic power provides high torque and smooth operation, making it suitable for machining large workpieces or components. Hydraulic rotary tables are favored for their robustness, high torque capacity, and ability to handle heavy workloads. They are widely used in various heavy industries where precise rotational control and substantial power are necessary to accomplish machining, assemble, and testing tasks.

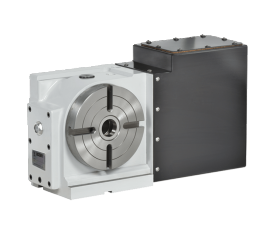

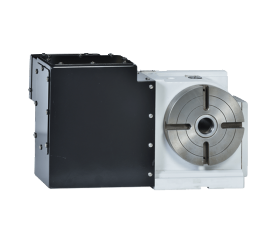

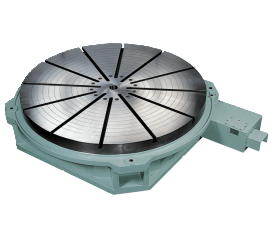

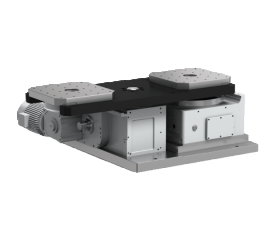

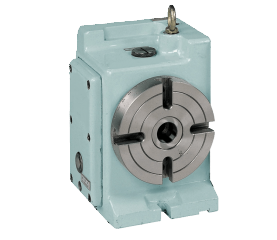

- Horizontal: Horizontal rotary tables are designed to rotate workpieces horizontally around a central axis, allowing for precise angular positioning around the circumference. Horizontal rotary tables come in various sizes and configurations, serving for both manual operation and CNC machining.

- Vertical: Unlike conventional horizontal rotary tables, vertical rotary tables rotate workpieces vertically. This configuration offers several specific uses and advantages in terms of space-saving, ease of use, and precision in vertical machining operations. They are widely used in various industries that require the machining of complex shapes, precise angles, and intricate designs on cylindrical or curved workpieces.

- Inverted: The table is mounted upside-down, so the rotary motion occurs vertically, with the workpiece or cutting tool positioned below the table. Inverted rotary tables are less common than traditional horizontal ones, and they are typically used in specialized machining scenarios that require unique workpiece positioning and access for specific machining tasks.

Versatile Applications of Rotary Tables Across Diverse Industries

Rotary tables find versatile applications across various machinery, including milling machines, CNC machines, grinding machines, and other specialized machines designed for specific manufacturing tasks. Rotary tables are pivotal for precise angular positioning and indexing, enabling operations such as contour milling, intricate part machining, and achieving fine surface finishes. Rotary tables are indispensable in manufacturing, ensuring precision and efficiency in a wide range of industrial processes.

Rotary tables can be used in a number of industries, to name a few:

- Aerospace: The aerospace industry demands high precision, reliability, and advanced machining techniques to produce components that meet stringent safety and performance standards. Rotary tables, with their ability to facilitate complex machining, precise positioning, and multi-axis operations, are instrumental in achieving these requirements and are extensively used throughout the aerospace manufacturing sector.

- High-tech: The high-tech industry encompasses various sectors, including electronics, semiconductors, robotics, telecommunications, and more. Rotary tables are valuable tools in the high-tech industry due to their ability to provide accurate positioning, multi-axis capabilities, and smooth rotational motion. They are instrumental in achieving the high level of precision and efficiency required in manufacturing cutting-edge technology products and components.

- Medical: The medical industry demands high precision and strict adherence to quality standards, and rotary tables enable manufacturers to achieve these requirements in the production of medical devices, implants, and instruments. The accuracy, versatility and consistent production of rotary tables make them indispensable tools in the medical manufacturing processes.

- Automotive: The automotive industry requires precision, efficiency, and versatility to manufacture various automotive components. They are used in numerous processes throughout the automotive manufacturing supply chain. Rotary tables enable multi-axis machining, precise angular positioning, and efficient production in the automotive industry. They contribute to the high quality and consistency of automotive components, helping to meet strict industry standards and deliver reliable products to consumers.

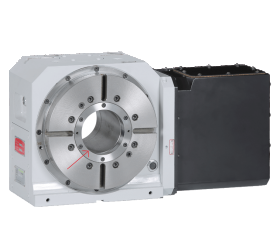

HOSEA’s Rotary Tables Enable Efficiency, Accuracy, and Productivity in Precision Manufacturing

Rotary tables play a significant role in the manufacturing processes of various industries where precision, efficiency, and versatility are essential. HOSEA has been a reputable exporter of 5-axis rotary tables, establishing itself as a leading supplier of CNC rotary tables, tilting rotary tables, and direct drive rotary tables.

HOSEA places a strong emphasis on quality, making it a priority throughout every stage of the production process. We take pride in manufacturing 5-axis and 4-axis rotary tables of high-precision, and adhering to the strictest standards of the European market has gained us widespread favor and usage in Europe. HOSEA is the first indexing table supplier in Taiwan to obtain the AS9100 aerospace-quality certification; notably, we proudly hold the title of the largest CNC 5-axis rotary table manufacturer in Taiwan, exporting over 300 CNC rotary table sets annually.

With over 55 years of experience in CNC development and manufacturing, HOSEA possesses the expertise to offer rotary tables that suit different manufacturing environments. HOSEA’s products are highly customizable and we provide our clients with comprehensive and tailored solutions.

Contact us to learn how HOSEA’s rotary tables can empower your industry today!