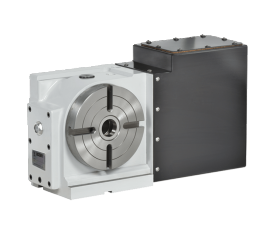

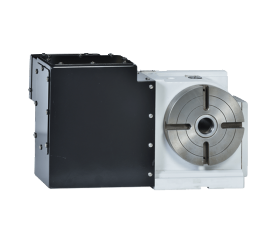

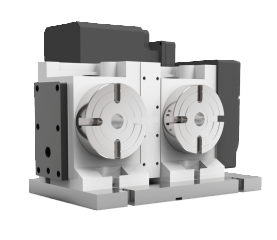

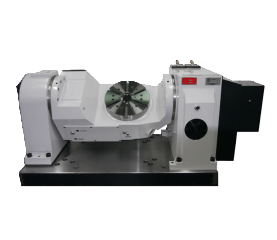

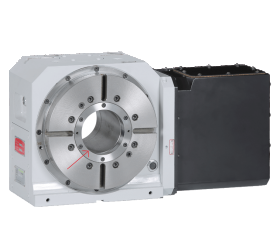

Product Description

E-catalog

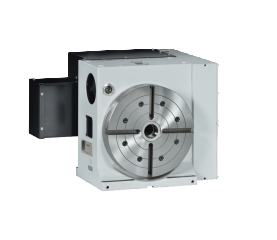

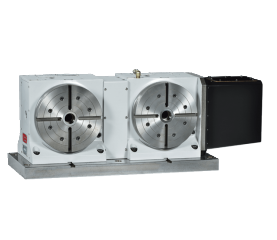

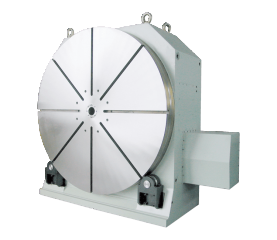

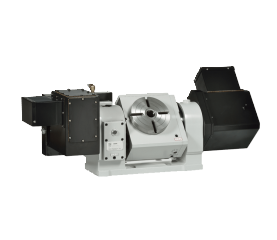

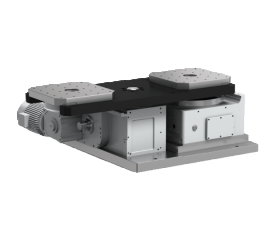

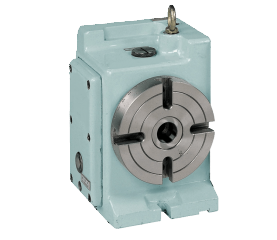

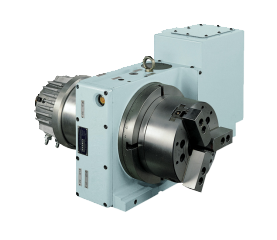

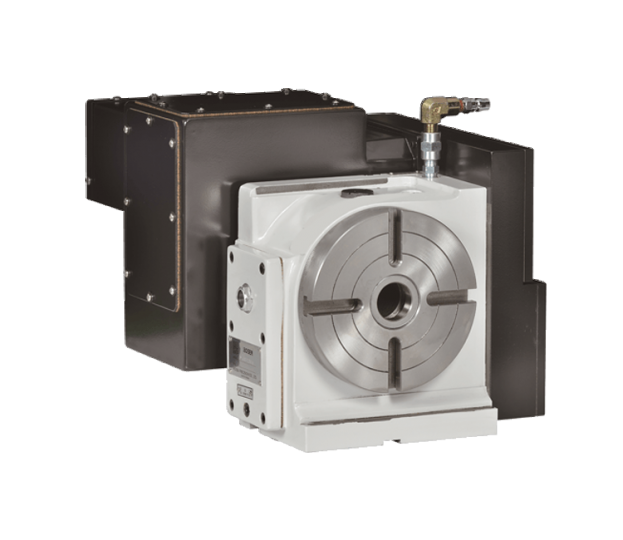

- Motor is mounted at backend

- 0.001° minimum positioning increment

- High rigidity structure: disk and shaft in a single piece – increased rigidity.

- Increased wear resistance –worm gear driveshaft

- High precision cross roller bearings

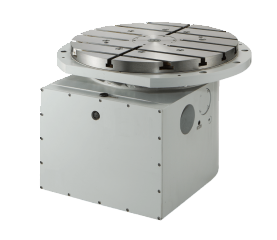

- Can be used in vertical or horizontal orientation

- Pneumatic clamping brakes

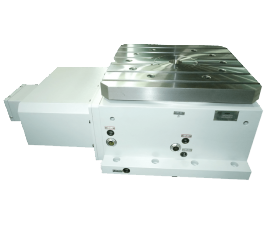

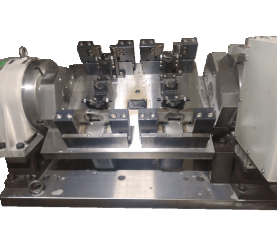

- Suitable for cutting: aluminum, copper, magnesium, and aluminum alloys.

- Machining applications: fine finishing, angular column cutting.

- High precision workpieces: medical applications, bicycle components, cell phones, precision sculpting, and 3C industry panels.

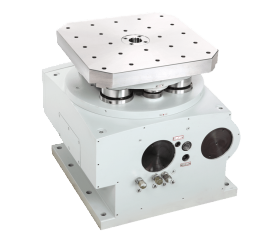

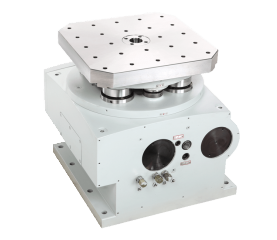

Standard Dimension

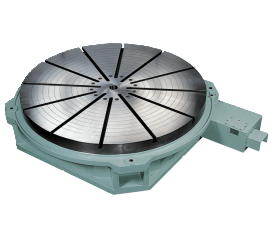

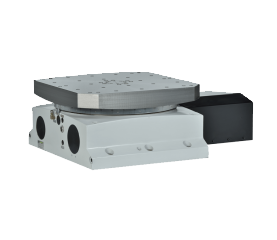

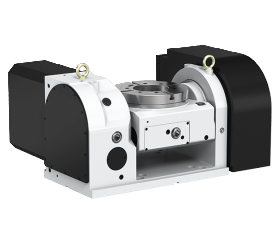

Product

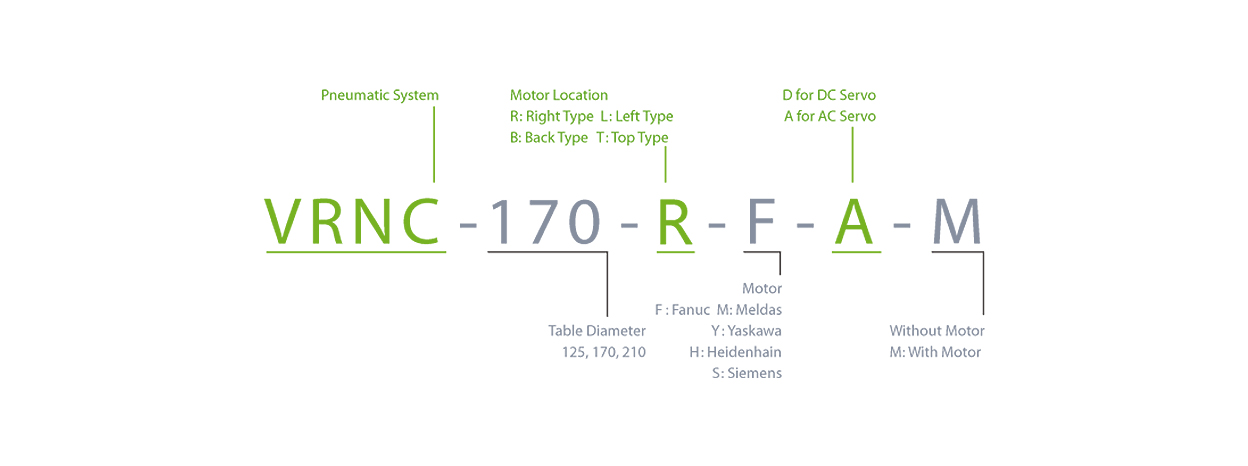

Reference

| Specifications / Model | VRNC-170B | VRNC-210B | VRNC-255B | ||||

|---|---|---|---|---|---|---|---|

| Worktable Diameter | Ø170 | Ø210 | Ø255 | ||||

| Center Height / Vertical | 135 | 160 | 160 | ||||

| Center Bore Diameter | Ø35H7 | Ø45H7 | Ø45H7 | ||||

| Width of T-Slot | 12h7 | 12h7 | 12h7 | ||||

| Width of Guide Block | 18H7 | 18H7 | 18H7 | ||||

| Number Of Guide Teeth | 72 | 72 | 72 | ||||

| Index Accuracy (sec) | 20" | 20" | 20" | ||||

| Repeatability (sec) | 4" | 4" | 4" | ||||

| Clamping Torque (Pneumatic 5kg/cm2) | 8 kg-m | 16 kg-m | 16 kg-m | ||||

| Load Capacity | Vertical | 75kg | 75kg | 75kg | |||

| Tail-Stock | 150kg | 150kg | 150kg | ||||

| Allowable Inertia Force (kg-cm-sec2) | 4.9 | 4.9 | 4.9 | ||||

| Allowable Turntable Torque | 15kg-m | 15kg-m | 15kg-m | ||||

| Weight (Motor Excluded)(kg) | 62.5 | 76 | 77.5 | ||||

| Servo Motor (Model As Required) | FANUC | MELDAS | FANUC | MELDAS | FANUC | MELDAS | |

| α4i | HF-54S | α4i | HF-54S | α4i | HF-54S | ||

| Reduction Ratio | 1/90 | 1/90 | 1/90 | ||||

| Minimum Input Increment | 0.001° | 0.001° | 0.001° | ||||

| Table Rotation Speed | 44.4 r.p.m | 44.4 r.p.m | 44.4 r.p.m | ||||

|

|||||||