Facilities

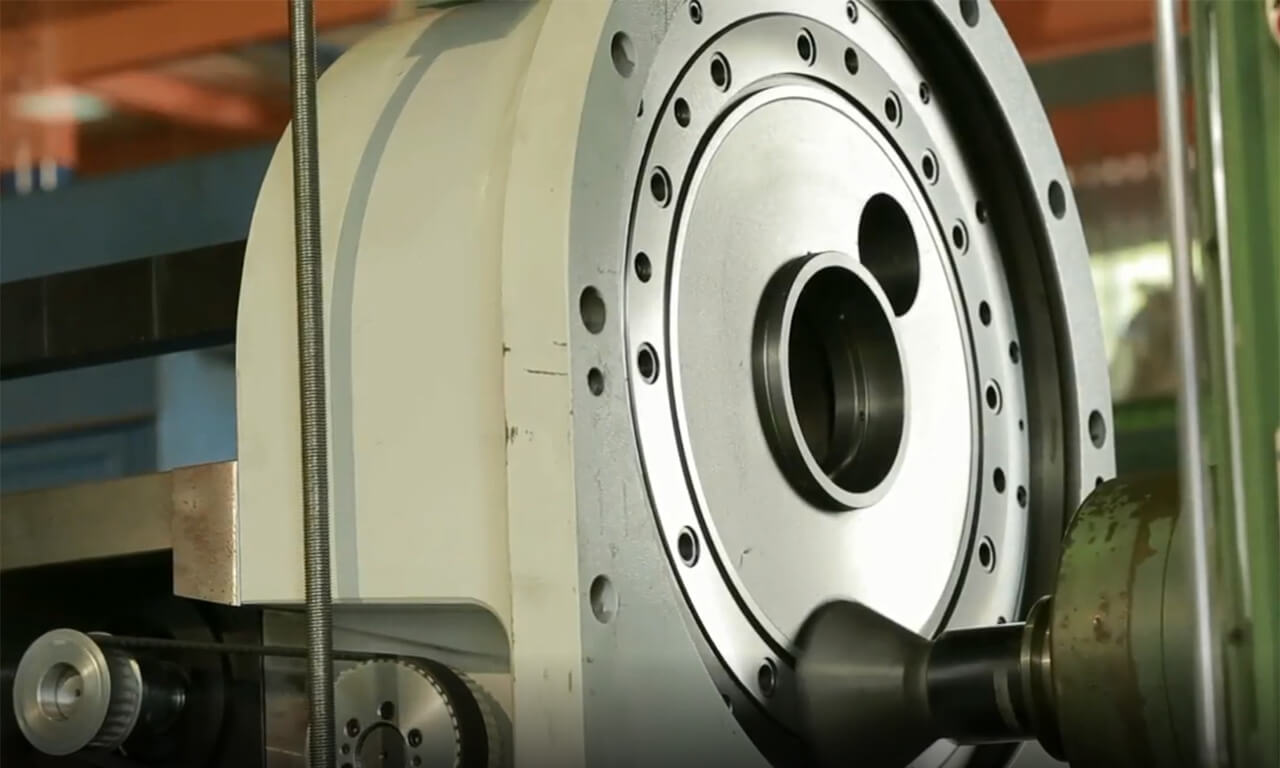

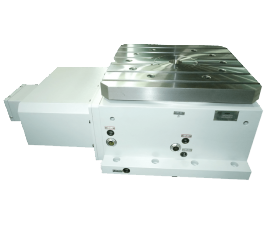

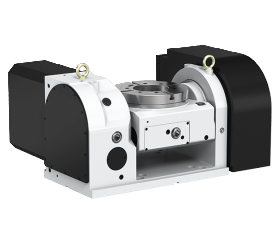

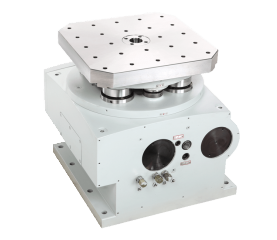

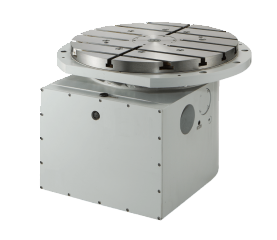

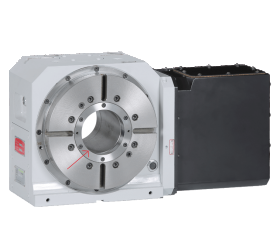

Special Machining:This machining center also allows us to perform 5 Face machining of more complex structures for the largest rotary tables whilst maintaining excellent accuracy at all times.

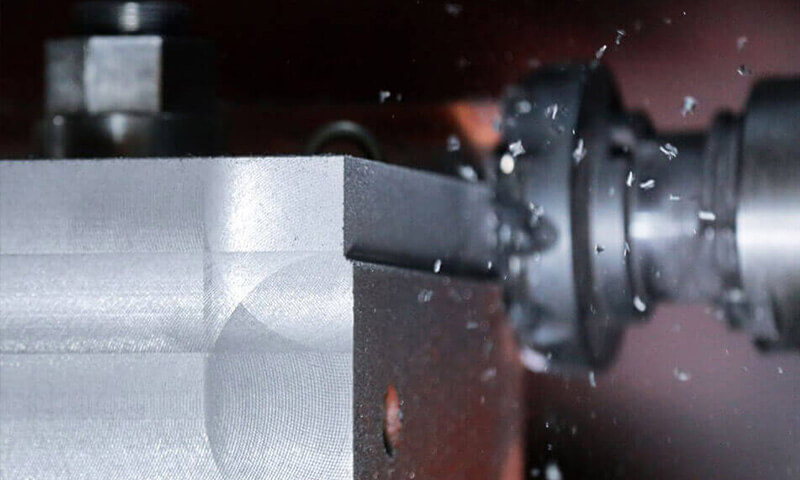

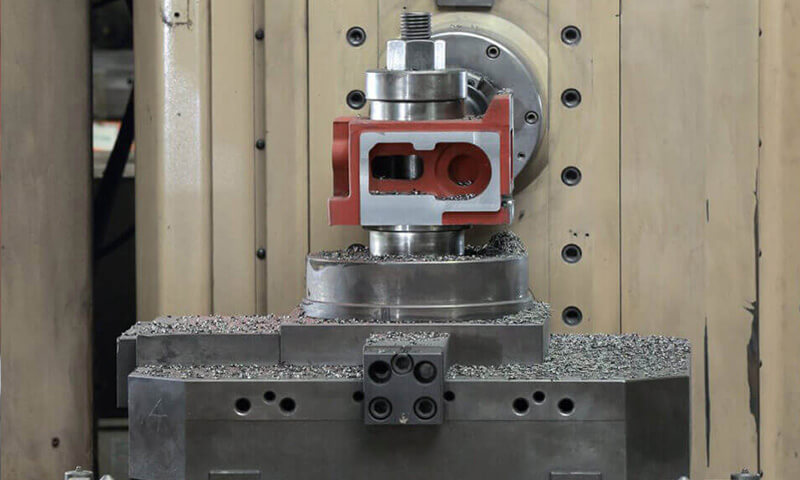

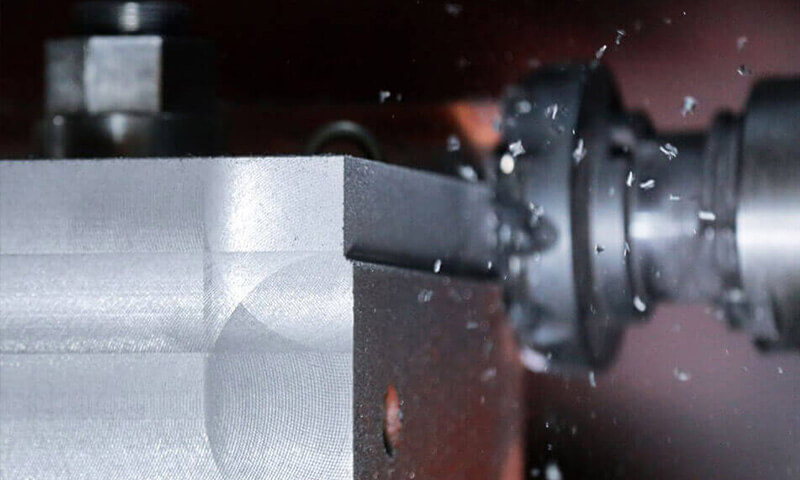

Horizontal Machining:Here we can see our Japanese Yasda horizontal machining center performing the initial cutting on one of the structures for our rotary table.

Done In One Machining:The Key advantage of using this type of horizontal machining center is that we can complete all aspects of the structure machining in a single set up. This not only improves our efficiency, but also guarantees stable precision by avoiding the need for multiple set ups on each piece.

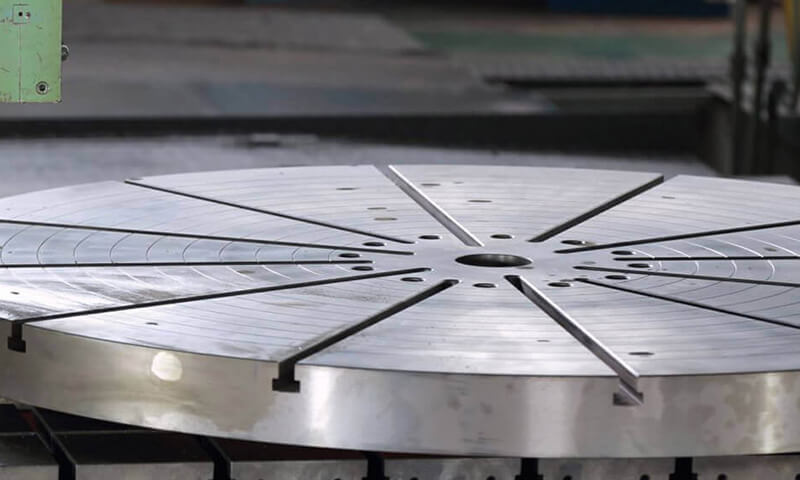

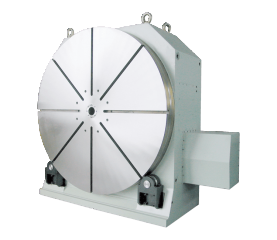

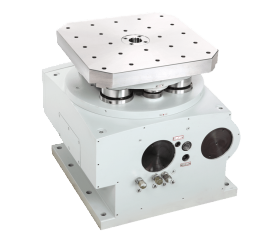

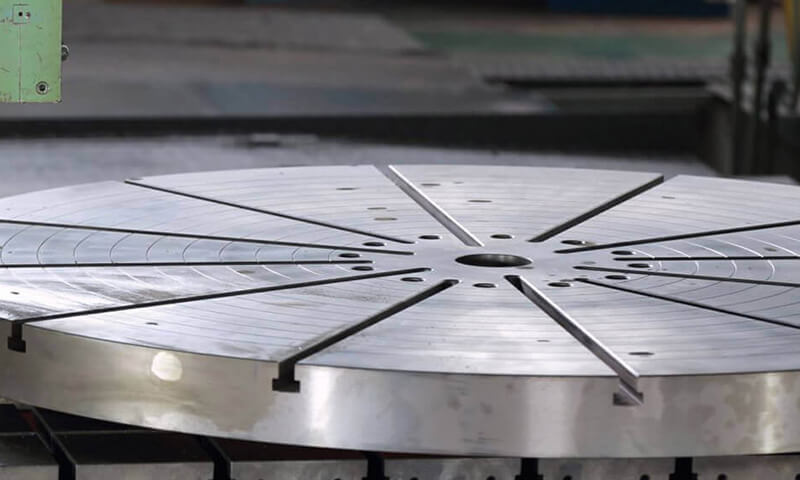

Large Machining Center:This is our Toshiba MPC3000 double column machining center. This machine delivers us the capability to machine work pieces up to 3000mm in diameter.

Production Equipment

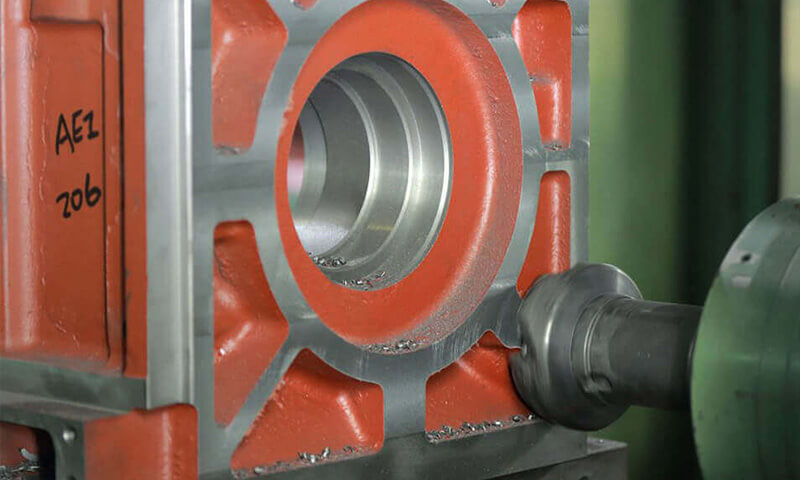

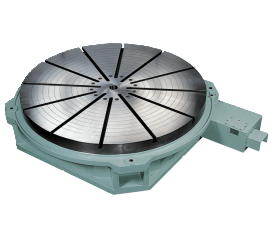

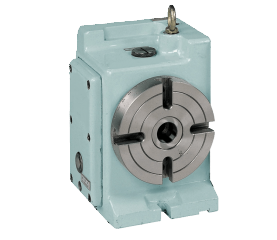

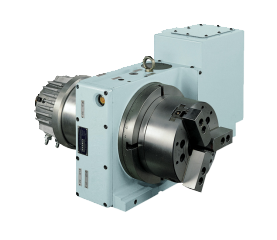

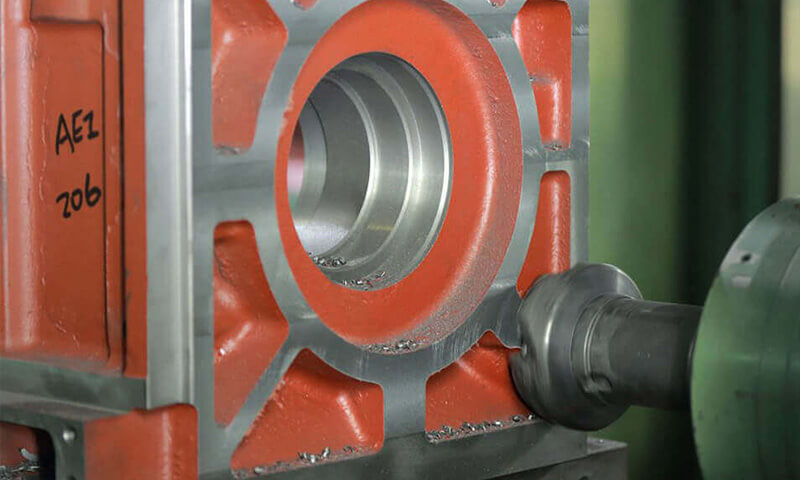

Vertical Lathe:This is one of our Japanese OM CNC vertical lathes cutting the main holes in the rotary table structure.

High Accuracy Machining:With this Japanese machine we can guarantee the accuracy of these components to ensure that we always produce the best for our customers.

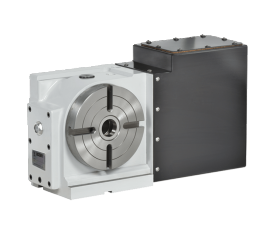

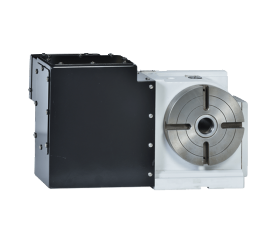

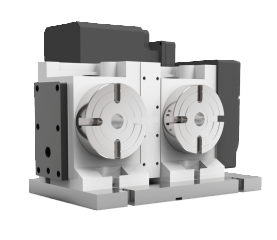

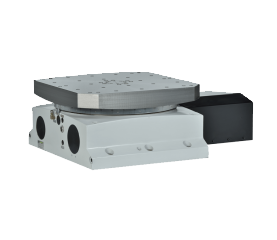

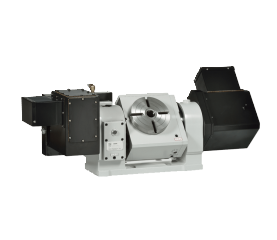

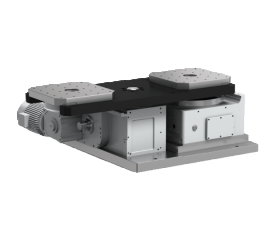

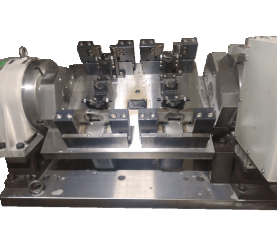

Horizontal Machining Centers with APC:This is one of our main horizontal machining centers that features a large APC system for the production of multiple components in the most efficient manner possible.

Single Set Up:With these machining centers we can set up 5 different work pieces at the same time, performing multi face machining on each of the different components in a single set up.

Rotary Table Structures:Here we can see the machining center working on the machining of several smaller rotary table structures.

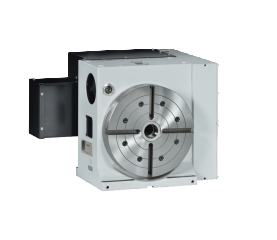

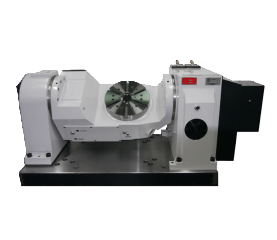

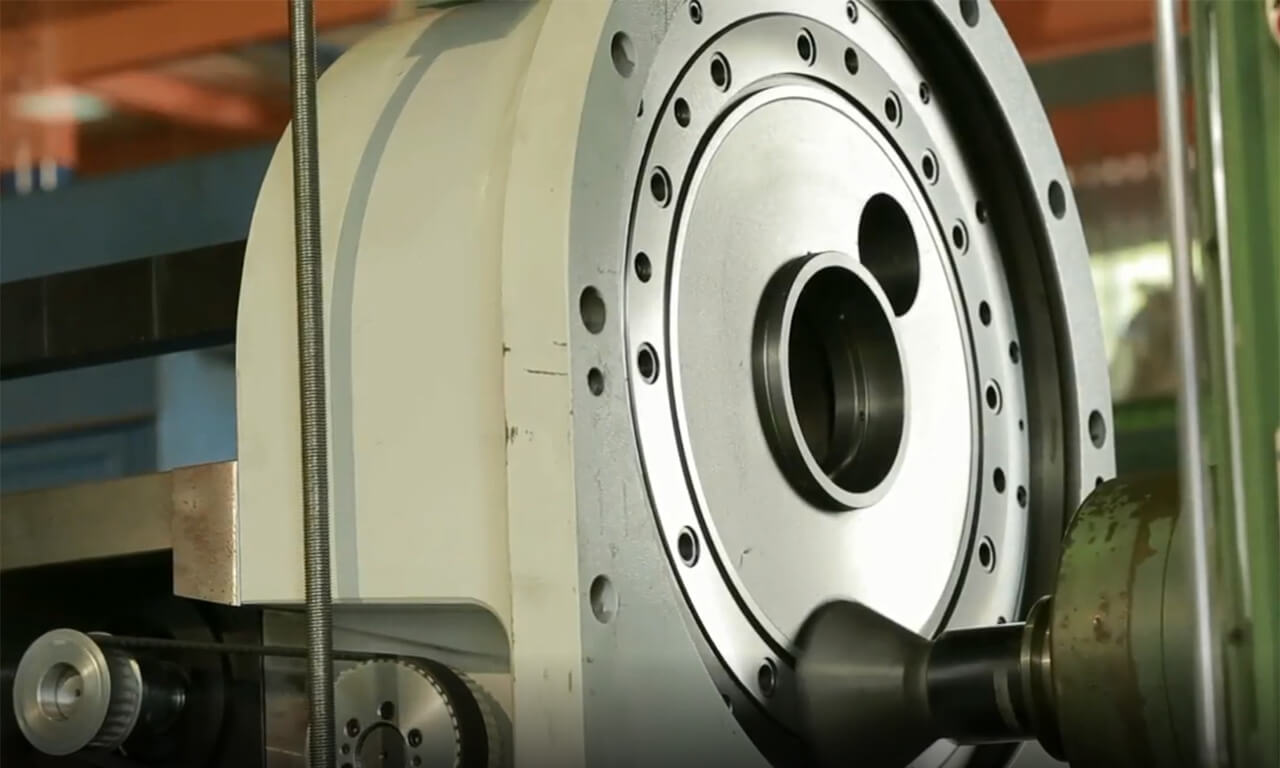

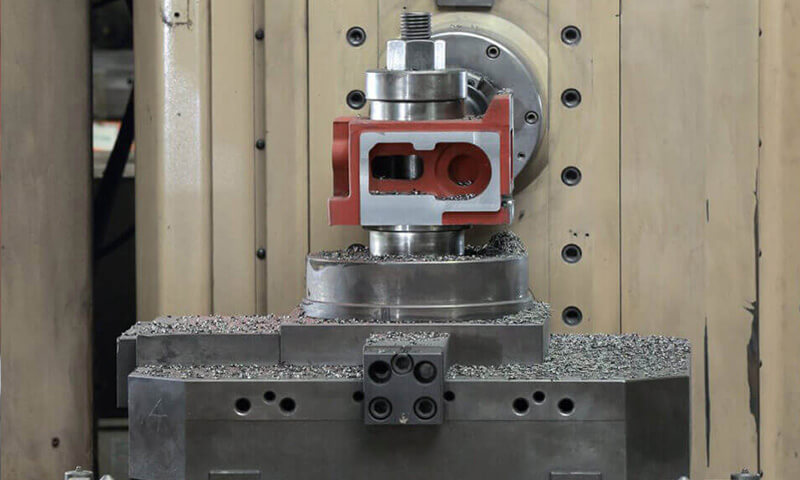

Rotary Table Machining:This is a key part of the production process in which we are cutting the central holes in the main rotary table structure.

Rotary Table Machining 2:This is a key part of the production process in which we are cutting the central holes in the main rotary table structure.

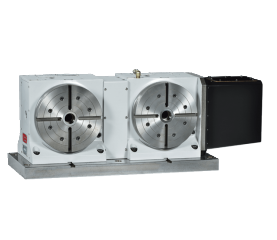

Machining Center APC:Here we can see the rotary table set up on the APC prior to machining.

Machining Center APC:Here the workpiece has now entered the machine and is being machined.

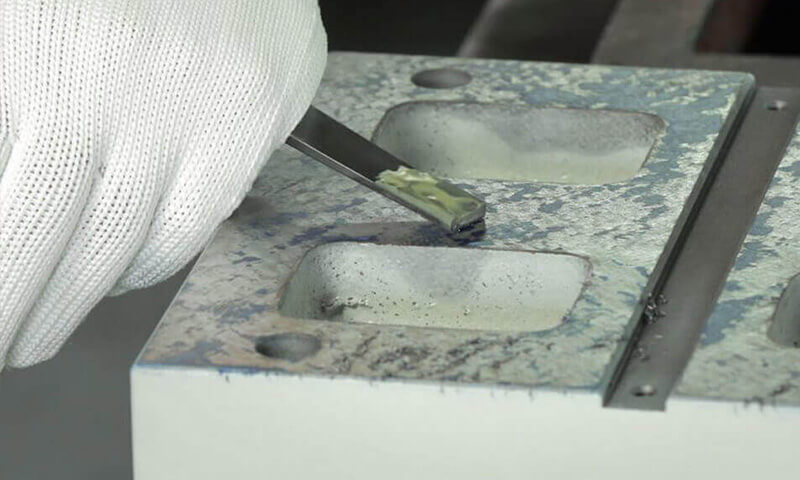

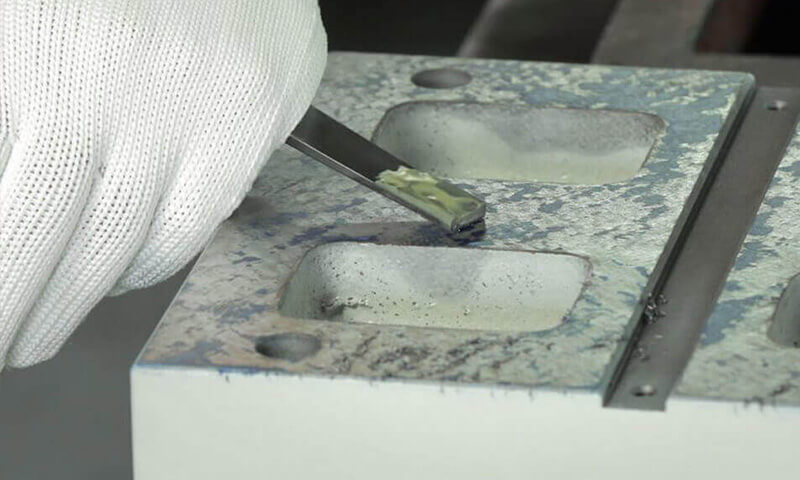

Hand Scraping:The hand scraping of the mating surfaces is vital to ensure the correct angle is presented for cutting.

Hand Scraping:Our experienced technicians perform all of the hand scraping in house to guarantee the precision of our components.

Hand Scraping – Final:Here we can see the final surface after the hand scraping is complete.