Smart Manufacturing: Elixir of Production Optimization

Smart manufacturing is transforming the landscape of modern production. Traditionally, manufacturing relied on mass productions, hence making it difficult to maintain sustainability throughout the entire value chain. But with smart manufacturing, factories can function with more flexibility. Smart manufacturing involves the use of AIoT (the fusion of Artificial Intelligence and the Internet of Things), big data analytics, and VR/AR to create a more efficient, productive, and connected manufacturing environment.

Smart manufacturing refers to the integration of advanced technology and artificial intelligence to optimize and automate the manufacturing processes. The more common smart manufacturing becomes, the more connected machines become through the Industrial Internet of Things (IIoT). Through this connection, machines will eventually be able to reach higher levels of automation. This means that one day machines will be able to automatically act and make the best decisions based on data and analysis.

Smart Manufacturing Enhances Production Efficiency

The difference between smart and traditional manufacturing processes is that the latter lacks flexibility. Traditional manufacturing process is the “batch-and-queue” method, which means a batch of products would be made and sent to the next step of processing no matter if they were needed or not. The products would then wait in line until they were used. This method was very costly and inefficient.

On the other hand, smart manufacturing finds opportunities where operations can be automated and use data analytics to optimize the performance or manufacturing. Smart manufacturing is a fully integrated system with the ability to respond in real-time to changing conditions and demands. This technological approach optimizes the manufacturing process and uses machines connected to the internet to monitor machine conditions.

Optimized Operation Process Outweighs the Costs of Implementing Smart Manufacturing

It's no news that being a trailblazer in the industry requires both vision and money. Implementing smart manufacturing can be a very expensive process. The reason behind the high cost is that all of the new technologies and systems must be integrated with the existing machines. However, the long-term savings of smart manufacturing outweigh the initial cost. This is why manufacturers are willing to switch to smart manufacturing.

The benefits of smart manufacturing include:

- Build the capacity for cost-effectiveness:

Reduction in product downtime means that machines can create more products. Sensors, diagnostics, and predictive AI technology will analyze the machines and notify operators when a problem occurs or could occur, ensuring rapid repair. - Optimize production and control delivery time:

Integrated AI helps to achieve the optimal manufacturing method as well as delivery time to ensure that customers are satisfied. - Maintain product quality and enable customization flexibility:

Utilizing smart manufacturing involves employing machines wherever feasible. Using machines means that products are more likely to have the same quality. Moreover, these machines are also very adaptive and are flexible enough to create product customization. - Improve performance:

Using information gathered with data analytics helps improve manufacturing performance. With the help of IIoT, sensors can be placed in manufacturing machines to collect data on their status and performance. Mechanical engineers will then be able to improve the manufacturing production and avoid any part failures by taking preventative measures in time.

Related post: [Link to blog post #1 Trends in Production]

What Makes Smart Manufacturing Possible?

Smart manufacturing involves the integration of various technologies to create an efficient and connected manufacturing environment. Some of these technologies include AI, additive manufacturing, IoT and IIoT – all of which form the foundation for implementing smart manufacturing systems, enabling manufacturers to achieve increased productivity and efficiency in their operations while harnessing the power of data and advanced technologies.

Being connected to the internet is an important part of smart manufacturing. Connectivity helps in production planning, better human-machine interaction, predictive maintenance, making process control intelligent and optimize material.

Smart Manufacturing in Practice

Let’s take a look at how technologies aid different aspects of smart manufacturing in practice:

- Data collection and analysis:

- Collecting data from clients: allows for the manufacturers to see if they are satisfying the clients’ expectations or if they should change certain aspects.

- Collecting real-time mechanical data: helps identify the state of machines or any possible failures.

- Advanced analytics tools, including machine learning and artificial intelligence algorithms, are used to collect, store, analyze large volumes of data, and ultimately enable real-time decision-making, optimize production processes and improve overall efficiency.

- Optimization:

- Higher interoperability: An integration of various systems and technologies to create a cohesive and interconnected environment (e.g., IoT devices, manufacturing execution systems (MES), enterprise resource planning (ERP) systems, etc.)

- Better human-machine collaboration: Applying augmented reality (AR), and virtual reality (VR) technologies to manufacturing processes.

- Improved teaching/training programs: Integrating AI into simulations has been found to be more efficient and time-saving as compared to traditional ways of teaching or training.

- Verification:

- Implementing AI into security adds efficiency, reliability and greater security because AI has the ability to make quick detections and to find a healthier solution to switch to without human intervention.

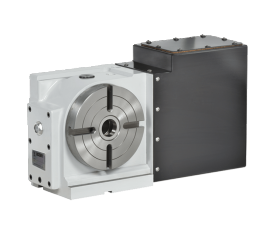

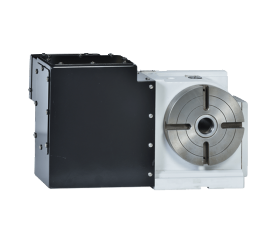

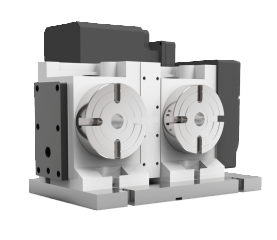

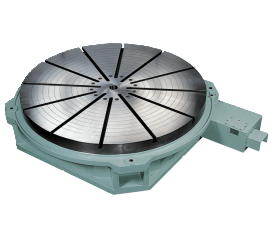

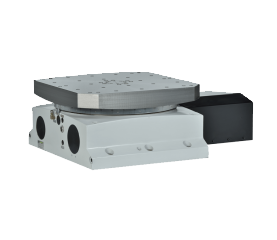

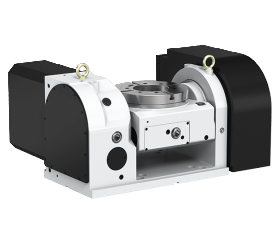

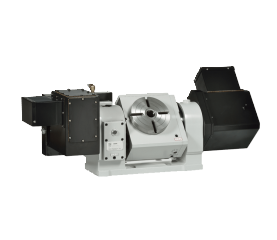

HOSEA can help you with our AIoT Solutions

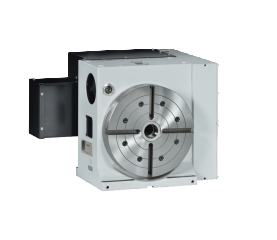

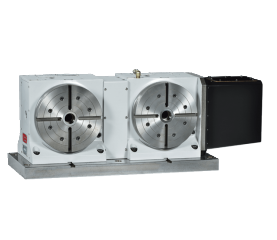

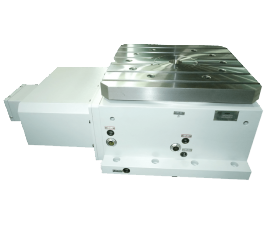

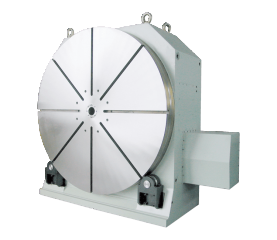

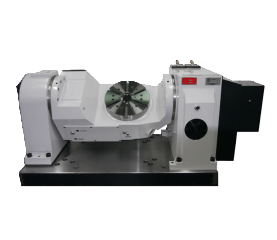

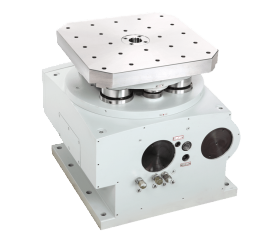

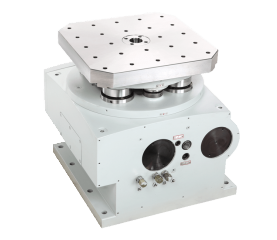

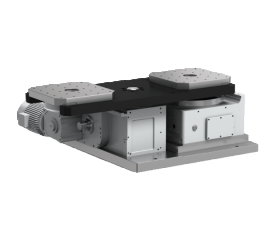

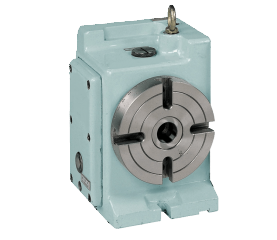

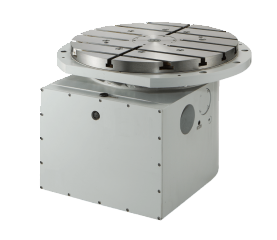

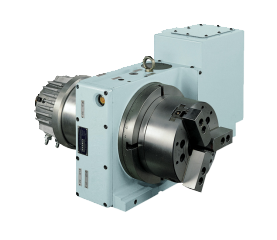

HOSEA, the preeminent smart manufacturing solutions provider in Taiwan, has a rich history in the CNC machining industry. We take pride in our worldwide acknowledgment for precision machining. HOSEA understands our clients’ pursuit of efficiency and reliability, and that’s why we are determined to help you transit to smart manufacturing.

HOSEA offers AIoT CNC Cloud Intelligent Service and AIoT Prognostic and Health Management that enable our clients in achieving smart manufacturing goals of near zero downtime, zero faults, and zero carbon emissions. HOSEA’s smart manufacturing solutions entail the following aspects:

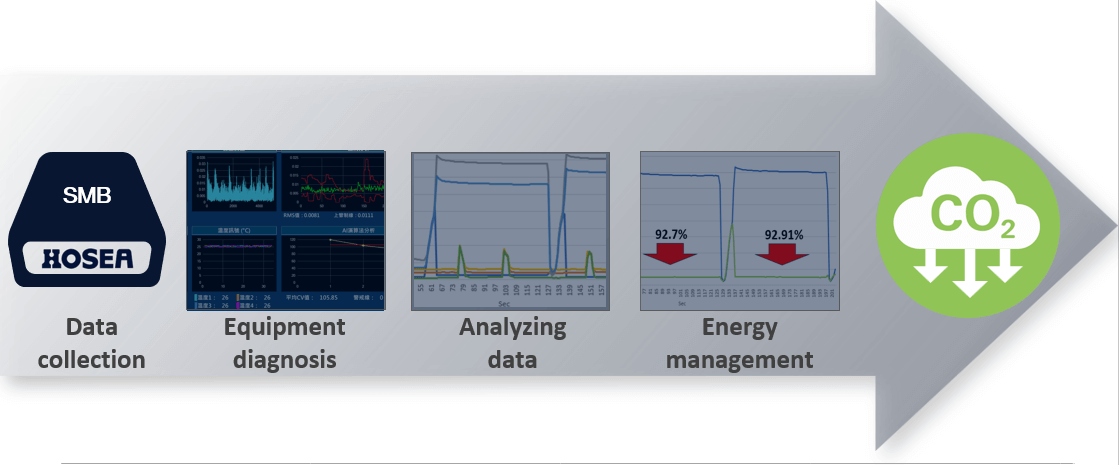

- AI Algorithm and Smart Machine Box (SMB):

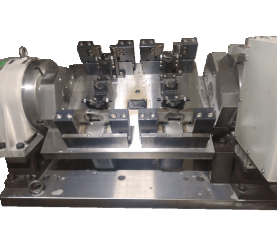

Connects machines and tools so that they are more easily accessible. Multiple sensors are used to collect information on the machines. SMB is also important for the painless upgrade of smart devices. - Equipment diagnosis:

Uses multiple sensors to monitor the machine and equipment to ensure that everything is working properly. Collects data and uses AI algorithms to determine and help prevent any future failures that could arise. - Cloud service:

Enables the client and manufacturer to remotely see the machine and its condition. Through the cloud service both the client and manufacturer will receive an alert if there is any problem with the machine. This will ensure rapid repair and lead to cost savings. - Energy management:

Maximizes the efficiency of equipment to help reduce the level of carbon emissions. This is to reach the overall goal of reducing carbon emissions to net-zero by the year 2050.

Enjoy Painless Upgrade to Smart Manufacturing with HOSEA

HOSEA promises to stand by you every step of the way towards smart manufacturing. HOSEA’s AIoT solutions ensure that our clients have painless, hassle-free upgrades to smart machining tools. Our products help you achieve:

- High efficiency and precision

- Data collection and AI analysis

- Real-time monitoring and maintenance

- Equipment optimization

Contact us to learn how HOSEA’s AIoT Solutions can help enhance your manufacturing process!