When AI Meets IoT: the Power of AIoT in Advanced Machining

In the realm of advanced manufacturing, the fusion of Artificial Intelligence and the Internet of Things (AIoT) has emerged as a game-changing paradigm. This convergence has given rise to remarkable innovations, such as the concept of the “smart factories.” These cutting-edge facilities represent a transformative leap in manufacturing, harnessing the power of automation, digitalization, and AI to redefine efficiency, precision, and operational continuity. In this exploration of smart manufacturing, we delve into AIoT solutions, uncovering their key features, benefits, and the profound impact they have on the manufacturing landscape.

AIoT: A New Chapter of Technological Integration

AIoT (Artificial Intelligence of Things) is the integration of AI (Artificial Intelligence) into IoT (Internet of Things) systems to enhance operational efficiency. This fusion improves human-machine interactions, data management, and analytics.

By applying AI techniques such as machine learning and deep learning, collected data from distributed nodes is effectively utilized. This approach brings machine learning capabilities closer to data sources, enhancing scalability, robustness, and data processing efficiency. AI benefits from IoT connectivity, signaling, and data exchange, while IoT gains value from AI's ability to process big data. This allows IoT to make analyses, learn, and decide autonomously.

Industry 4.0: Application of AIoT in Manufacturing

AIoT can be applied in different fields. For instance, AIoT enables automated vehicles capable of safe driving without human intervention. These vehicles collect real-time data on surroundings, driving conditions, and pedestrians to make optimal driving decisions.

Beyond vehicles, AIoT enhances manufacturing processes by enabling real-time monitoring of machine conditions. This aids in detecting and replacing defective parts before they worsen. AI models analyze real-time video feeds for quality control, improving manufacturing quality.

There are many benefits to apply AIoT in manufacturing:

- Enhanced efficiency: Using machine learning methods allows AIoT-powered machines to generate and analyze data and recognize patterns. This ensures quick operational insights, finding and fixing problems, and improving manual process automation.

- Improved maintenance: Collecting more data allows for a more efficient maintenance process which will reduce costs, waste, and downtimes. The more data there is, the more helpful AI can be in adjusting to certain specific needs.

- Advanced analytics: Analyzing can be done by AI. This saves more time and money in comparison to human analysis.

- Increased security: Utilizing the vast amount of data collected from IoT, AIoT can leverage this data to make real-time decisions. This capability enhances security and aids in risk management. AIoT also possesses the capability to predict outcomes and implement preventive measures.

Potential and Challenges of Applying AIoT to Transform as Smart Factories

Utilization of AIoT in manufacturing brings about potential as well as challenges. One of the potentials is transforming the landscape of conventional factories. A smart factory is an automated manufacturing process that operates with minimal human intervention, relying on automation and digitalization. This approach enables continuous production around the clock, significantly reducing labor costs, energy consumption, and carbon emissions.

While a smart factory enjoys the benefits including improved operation efficiency, better production consistency, and more advanced maintenance strategies, there are several challenges it faces:

- Process integration: Ensuring that both AI and IoT are compatible with each other is an important step in integrating AIoT. This reduces the need for extra hardware or software.

- Data collection: Collecting data is an important part of AIoT as it is required for the system to make the best real-time decisions. However, there are a few problems that can arise with data collection. There may be a lack of data availability as sometimes data does not cover the full scope of what is needed. There may also be data bias. Although AI is meant to be unbiased, sometimes bias can be unintentionally trained into the system. Data quality as well as high costs involved in the collection of data are other challenges that are included in data collection.

- Cybersecurity and software automation: Monitoring of security being done by AIoT instead of humans increases the chances of mistakes going unnoticed. This can lead to a large amount of scrap parts worth thousands of dollars or serious damage being done to the machines.

- Human resource and training: Making up for the lack of skill sets is a major part of implementing AIoT. As this system requires new technology, a highly skilled team will be necessary to install and monitor the process. However, the hiring or finding a skilled team will add to the cost of implementation.

- System and equipment upgrade: Implementing the system requires a large initial cost. However, there are many long-term cost savings that come with the implementation. The system is also complex and requires careful planning and execution to ensure it is properly done.

Build an Automated Future: HOSEA’s AIoT Solutions in Precision Manufacturing

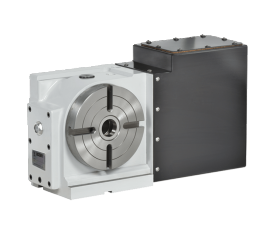

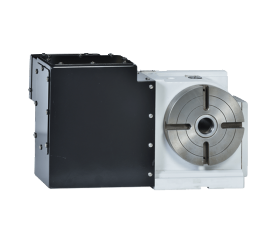

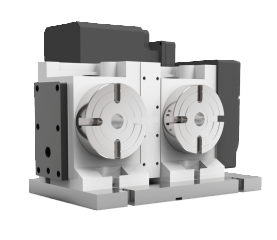

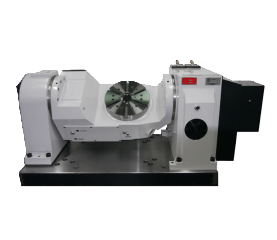

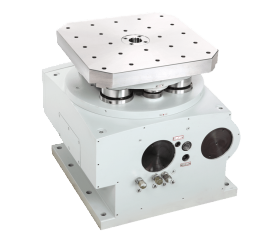

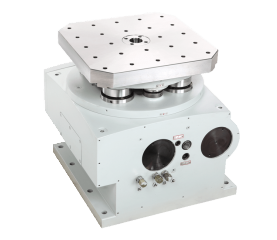

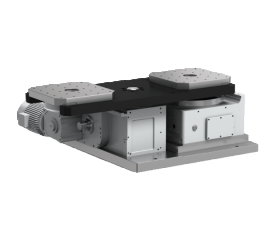

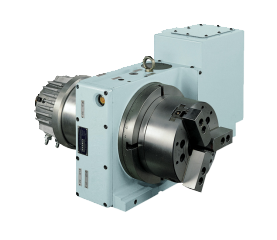

HOSEA has over 55-years of experience in the CNC machining industry, and we take pride in our international recognition for machining accuracy during processing. Serving as a trusted CNC machine ODM company for our Germany partners, HOSEA has met the most stringent standards in the European market. Furthermore, as the first indexing table supplier in Taiwan to obtain AS9100 aerospace-quality certification, we demonstrate our commitment to excellence and quality.

Besides our never-ending effort in pursuing perfection, HOSEA understands that well-preparedness remains a priority for our clients. Therefore, HOSEA offers AIoT solutions for the industry to achieve near-zero downtime, zero faults, and zero carbon emissions.

HOSEA always keeps our clients at heart. Introducing HOSEA’s AIoT Prognostic and Health Management and AIoT CNC Cloud Intelligent Service that enable our clients to take one step forward in precision manufacturing:

AIoT Prognostic and Health Management

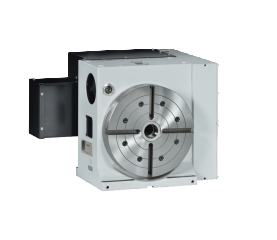

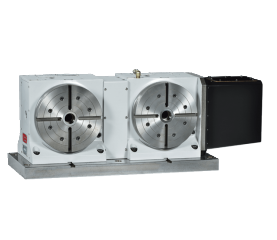

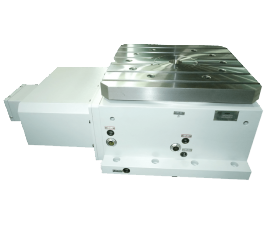

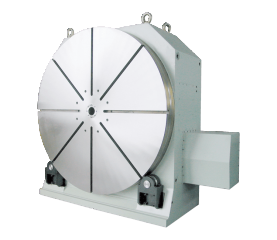

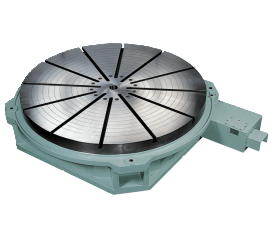

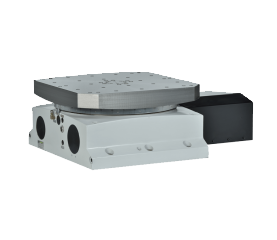

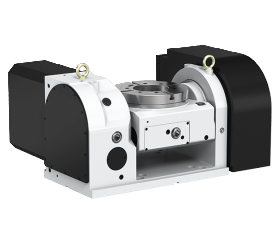

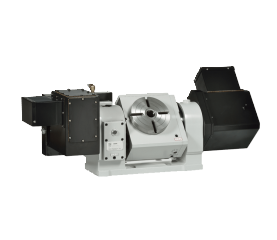

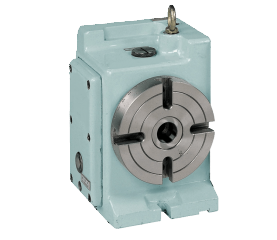

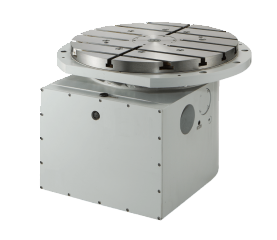

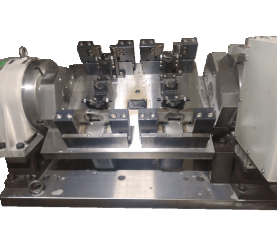

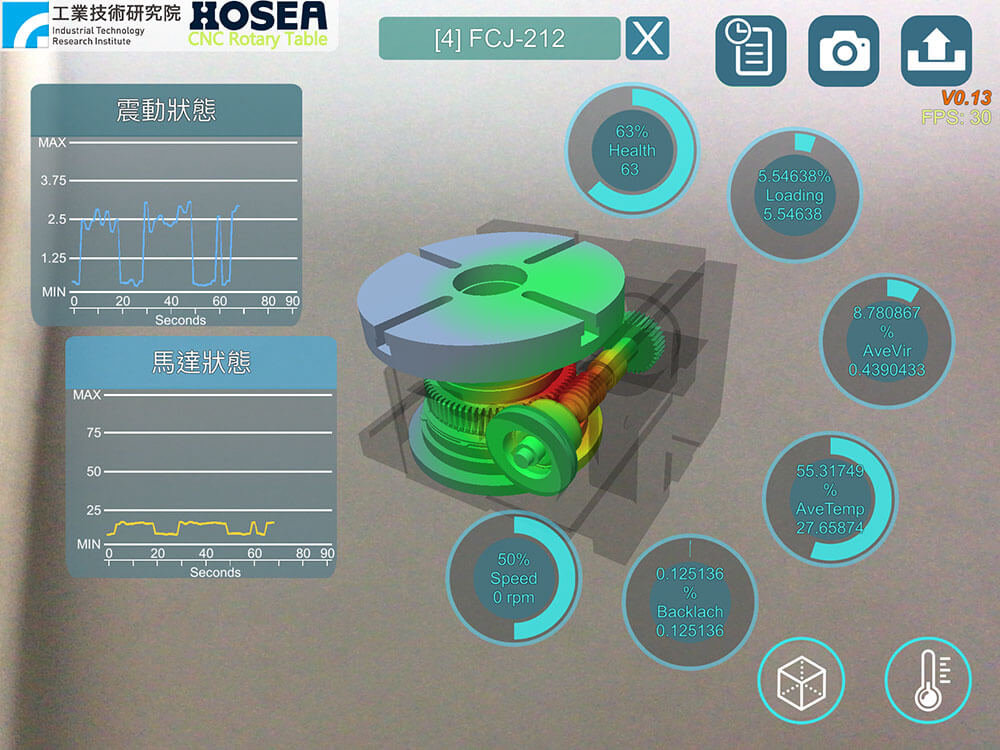

HOSEA’s AIoT Prognostic and Health Management focuses on high precision and process optimization. The system utilizes AI to balance the rotating axes and client machines, involving precise data collection and parameter setting for optimizing equipment performance. This AIoT solution not only extends equipment lifespan but also guarantees precision. By employing data collection, analysis, final optimization, and verification, equipment performance is tailored to controller needs. HOSEA integrates vibration, current, temperature, and IO models for equipment monitoring. Collected data is processed using AI algorithms to assess stability and operational range for the equipment.

AIoT CNC Cloud Intelligent Service

HOSEA understands that our clients have diverse needs; that's why we customize our products to suit various machine conditions. For machines needing high load, high rigidity, and high speed, HOSEA’s AIoT CNC Cloud Intelligent Service can give a complete solution. We also provide customizations for machines that require high precision, fine tolerance or hydrostatic rotary tables.

In addition, HOSEA’s AIoT CNC Cloud Intelligent Service can reduce safety concerns and prevent equipment from further damage. When problems occur during the machining process, HOSEA’s AIoT CNC Cloud Intelligent Service allows the sensors to send signals to the cloud service system indicating the problem. Both the user and the manufacturer will receive abnormal signals and can immediately conduct a preliminary inspection and repair. This ensures that any defects are solved immediately to avoid any further damage to the equipment.

Upgrade Your Manufacturing Process with HOSEA’s AIoT Solutions

The marriage of Artificial Intelligence and the Internet of Things (AIoT) stands as a revolutionary force within the realm of advanced manufacturing. This dynamic fusion has given birth to extraordinary innovations like “smart factories.” These smart facilities symbolize an evolutionary stride in manufacturing, leveraging the combined potential of automation, digitalization, and AI to redefine the very essence of efficiency, precision, and operational seamlessness.

This exploration into smart manufacturing has provided an insight into the field of AIoT solutions, unearthing their pivotal attributes, advantages, and the profound and enduring impact they are exerting upon the vast landscape of modern manufacturing.

The unfolding potential of AIoT underscores a future where innovation and efficiency coalesce.

Contact us to learn how HOSEA’s AIoT Solutions can advance your machining process.